FABRICATION & PACKAGING

What differentiates Roterex from the competition is our ability to design and create premium turnkey products in-house. Our team of industry professionals specialize in various aspects of the fabrication and packaging process, contributing their unique skills to the finalized product. The Roterex shop offers engineering, design, electrical, instrumentation, welding, mechanical and pipefitting all under one roof.

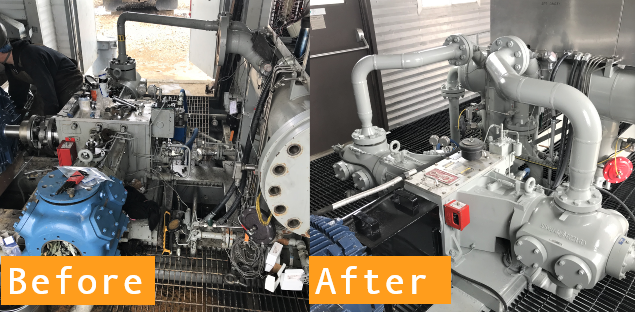

We utilize existing inventory by optimizing our client’s current assets, or accessing pre-owned equipment for purchase. While we also build new units, we understand our customers’ need for cost control. By re purposing used equipment, our clients can expect substantial cost savings, as well as faster turnarounds on production.

We pride ourselves on packaging superior and cost-effective oilfield equipment with a consideration for our clients’ budget, all in a timely manner. Roterex is schedule driven while never compromising on our superior quality.

COMPRESSOR RETROFITS

Roterex has a dedicated team of professionals with extensive experience in compressor retrofitting. Our knowledge and responsiveness make Roterex the clear choice to keep your equipment operating reliably and efficiently.

RETROFIT CAPABILITIES

- Compressor restaging (2 to 3 stage configuration)

- Compressor recylindering

- Natural gas engine to electric motor conversions

- Sweet to sour conversions

- Cooler rebundling

- Piping modifications

- Control panel upgrades

- Noise and emission reductions

- Engine overhauls

- Vessel repairs and alterations

RETROFIT FOLLOW UP

- PSV recertification and reports

- Updated drawings (P.Eng stamped)

- Updated bill of material, line lists, etc.

- Test run

- Field start up assistance

- Full ABSA Quality management package provided